- 833-MP2PLASTICS

- info@mpsquared.net

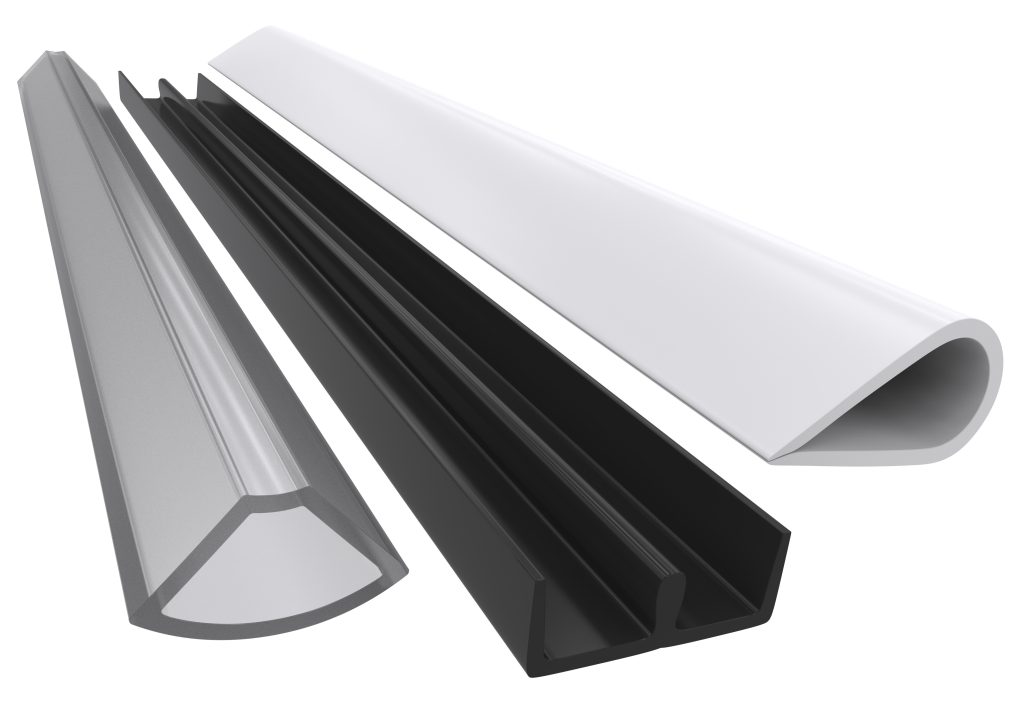

Profile & Custom Extrusions

Parts & Components

Menu

Get a quote

Profile Extrusion

Profile extrusion is a continuous high-volume manufacturing process where a polymer material, enriched with the desired additives, is melted and pushed thru a die supported by a source of air to allow the hollow product to maintain its inside shape and not collapse in a vacuum. Continuous shapes in varying lengths can be produced quickly and efficiently. Various wall thicknesses, colors, textures and material modifications are available. We build our extrusion dies, calibrators, and plates in-house for quick turnaround and fast adjustments. Two or more machines can be used to feed a single die head in order to create multiple material components (e.g. combination of colors, functional materials, hard/soft combinations etc.). Custom materials and additives give the part additional performance characteristics, such as fire resistance, durability, anti-friction, or conductivity properties.

Profile Extrusion Capabilities

- Rigid Profile Extrusions

- Flexible Profile Extrusions

- Dual-Hardness Extrusions

- Clean Environment / Clear Material Extrusions

- Multi-Material Extrusions (2K, 3K)

- Shapes up to 10”/25 cm diameter/cross-section

- Shapes down to 0.4”/10 mm

- High- and Low Volume Runs

Materials for Profile Extrusion

- All Thermoplastic Materials, no PVC. Most common materials are PC, PA12, TPU, TPE, PMMA, HIPS, ABS, PA11 and others.

Application Examples

- Recreational products

- Tubing

- Sealing sections

- Edging

- Automotive

- Marine

- EV Cooling

- Telecommunications

- Irrigation

- Medical

- Agriculture

- Magnetic

Secondary Operations

- Ultrasonic Welding

- Close Tolerance Cutting

- Hole Drilling

- CNC Routing

- PVD Coating

- Anti-Scratch / Hardcoat (Temperature or UV triggered)

- Assembly

- Electronics Integration

Ideas to reality

Ask an Engineer

We are driven by innovation, quality, and customer satisfaction. Partner with us and unlock the full potential of polymer materials for your next project. Contact us today to explore how our advanced solutions can elevate your applications to new heights.

The Plastics People.

Contact

- 2175 Curtis Road, Addison Twp, MI 48367

- info@mpsquared.net

- 833-MP2PLASTICS

© 2023 MPSquared. All Rights Reserved.