- 833-MP2PLASTICS

- info@mpsquared.net

Rubber & Metal Components

Parts & Components Manufacturing

Menu

Get a quote

Stamping

Critical tolerance stamped and machined parts for a broad spectrum of OEM customers. Areas we service so far include automotive; heavy truck; pumps and valves; medical; aerospace and machinery. We supply through manufacturers that produce simple to highly complex tooling for the production of precision stampings and parts to OEM spec. Secondary fabrication processes available include bending; forming; drilling; notching; punching; milling; precision sawing; mitering; welding; cutting; piercing; boring; 3-axis/5-axis CNC machining; lapping; and grinding. Submit your print and requirements for a quote for traditional stamping, progressive stamping and fine blanking!

Thixomolded Parts / Advanced Metal Castings

Thixomolding is a process for injection molding of magnesium alloys. This process results in less porosity and improved fatigue strength over conventional die-casting. Further advantages are:

- High conductivity; electrical, and thermal.

- Withstands high operating temperatures.

- High dimensional accuracy and stability.

- Exceptional thin wall capability (0.5–1 mm)

- Good environmental corrosion resistance.

- Good finishing characteristics.

- Full recyclability.

The main applications are castings and heat sinks for electronic devices, automotive components, medical, and aerospace. Based on the surface finish, post-processing is required. The laminar flow front created during the Thixomolding® process ensures the production of components with more uniform material structure and lower porosity and/or cavity-free compared to die casting. Ask us for more detail…

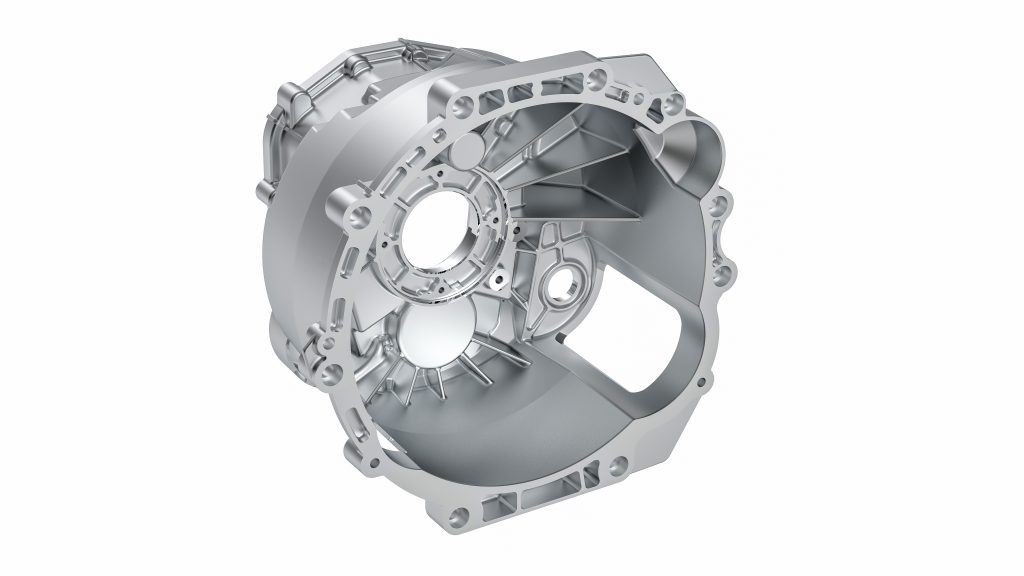

Castings & Forgings

We supply quality build-to-print castings & forgings from manufacturers that utilize state-of-the-art methods. Critical tolerance casting and forging products from manufacturers per the most demanding OEM specifications in a broad spectrum of industries. We supply competitive high-quality precision parts from a wide range of materials and advanced forging and casting technologies, such as investment casting, aluminum, and magnesium die casting, sand casting, and permanent mold casting and impression die forging, open die forging, cold forging and seamless rolled ring forging in ferrous and non-ferrous metals.

In addition, further part finishings can be provided: heat-treating, welding, etching, NDT, and FAI. We use an array of materials, including aircraft alloy, aluminum, copper, ductile iron, iron, magnesium, nickel alloy, stainless steel, steel, titanium, zinc, and more. Depending upon the size, demand, and/or other criteria turnaround times vary. Talk to us and let us provide you with a quote!

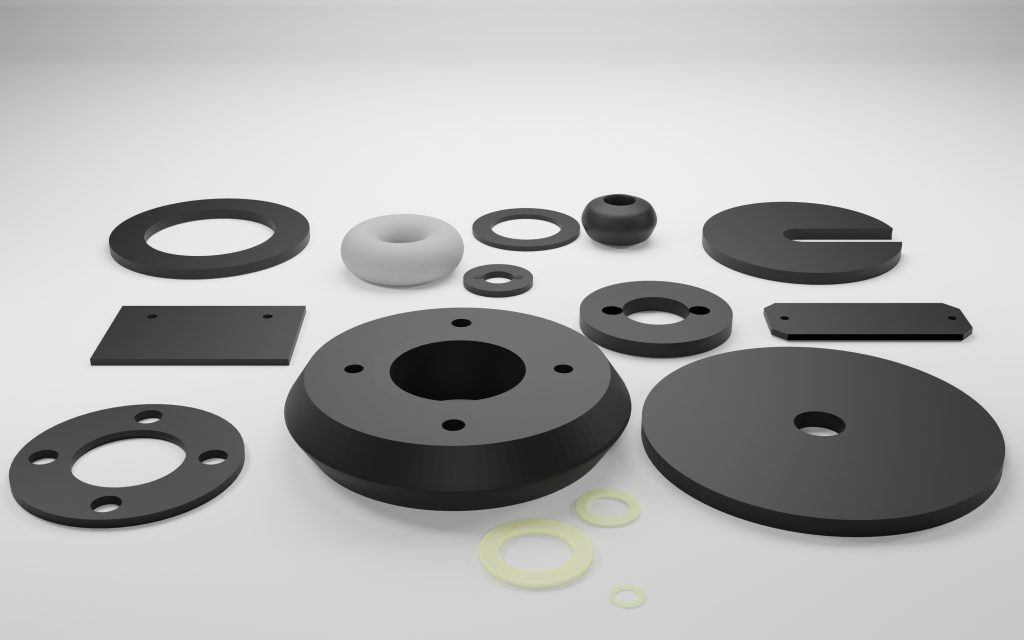

Rubber Products

(MP)Squared utilizes a partner with a global network of manufacturers to supply the aerospace, automotive, and industrial machinery industries with world-class rubber, as a specialty supplier, we can source a wide range of precision products produced with state-of-the-art molding technologies designed to meet the most demanding OEM specifications. Products include precisely compression molded or extruded synthetic rubber (NR, BR, NBR, EPDM, Neoprene, Viton) products for automotive and industrial applications as well as polymer products combined with heat-activated or pressure-sensitive adhesive tape, or nylon cloth enforced, or rubber-to-metal bonded items. Our suppliers adhere to the requirements of U.S. and international standards for manufacturing and quality control. Parts are delivered when and where you need them including PPAP and process control documentation, created from electronic monitoring devices if desired.

Applications are:

- Industrial Seal and Oil Seal

- Reinforced Diaphragm

- Gaskets (up to 3.5 x 3.5 m)

- Rubber to Metal Bonded

- Rubber Fender & Roller

Die-Cut Foam Gaskets & Expanded Foam Rubber

SealTec Foam materials are available in a broad range of thicknesses, hardness, densities and colors. All cellular rubber materials are available with pressure-sensitive adhesive (PSA) backing. We are specialized in precision die-cut gaskets and expanded foam rubber products for diverse applications and industries in North America. We utilize our own custom built-to-print tools for several different methods of die cutting depending upon the customer’s specification. Expanded Foam Rubber is available open- and closed-surface cell.

Our cellular rubber is different because it has a defined cellular structure making it less hard and dense but more heat resistant and absorbent.

Since material (mass) per unit volume reduces, there are cost benefits to using less material. Thanks to the pockets and cells in cellular rubber, it has excellent compression set at high elongation. Some cellular rubber materials are best used to insulate low-temperature systems, while others thrive on higher-temperature applications. Some have a great ability to absorb shock, others have flotation capacity and fluid immersion.

Our main focus is on the conversion of cellular rubber products into a variety of products from gaskets, seals, NVH protection, assembly support etc.. Our SealTec products are used in HVAC, construction, automotive, medical, consumer products and throughout general industry. Do you have other questions about cellular rubber or need help choosing the right material? Let’s get started and contact us.

Ideas to reality

Ask an Engineer

We are driven by innovation, quality, and customer satisfaction. Partner with us and unlock the full potential of polymer materials for your next project. Contact us today to explore how our advanced solutions can elevate your applications to new heights.

The Plastics People.

Contact

- 2175 Curtis Road, Addison Twp, MI 48367

- info@mpsquared.net

- 833-MP2PLASTICS

© 2023 MPSquared. All Rights Reserved.